This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Researchers create a breathable alveolus in vitro

Researchers from Zhejiang University have successfully constructed biomimetic alveoli outside the human body that can replicate the process of human breathing.

How to simulate the diverse deformations of alveoli in the body? How to construct a air-liquid interface with suitable materials? These are still problems to be solved in the construction of alveolar models in vitro.

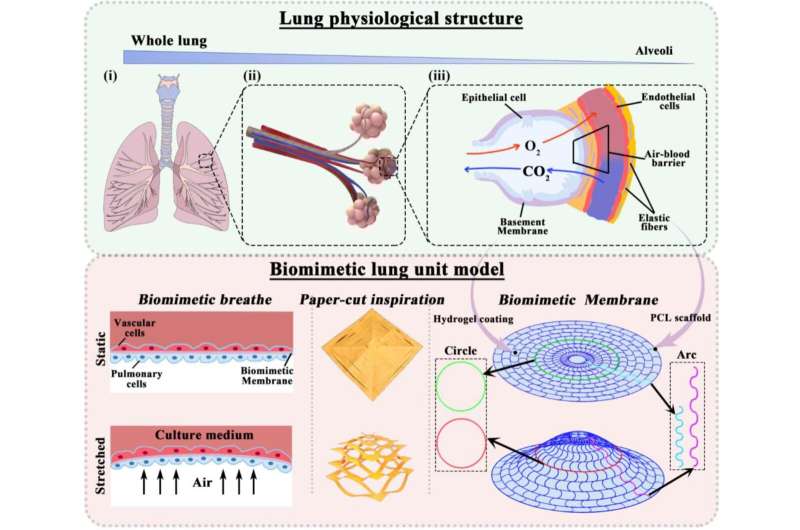

Inspired by paper cutting, the research group designed a novel biomimetic controllable strain membrane (BCSM) to simulate the alveolar basement membrane, realizing an air-blood barrier and biomimetic respiration for cell mechanism research and drug screening.

The study, published in the International Journal of Extreme Manufacturing (IJEM), details the methodology for creating the structure of the alveolar basement membrane and biomimetic lung unit model, allowing for the simulation of both normal and abnormal states of human respiration. The research holds significant potential for promoting new drug development, understanding alveolar development, and identifying disease targets.

"Chronic respiratory diseases rank among the world's top four chronic diseases, making the development of new treatments for lung diseases both significant and valuable. However, the process of developing new drugs is fraught with challenges, including high risks, lengthy timelines, and substantial costs. The key issues at hand are how to reduce research and development costs, increase success rates, and devise new methods for drug evaluation," said Professor Yong He from Zhejiang University.

The alveolar microphysiological system is a groundbreaking scientific tool that replicates the structure of the body's primary respiratory unit, the alveoli, in vitro. "This system provides a model that more accurately mirrors human physiology and is anticipated to bridge the gap between clinical experiments and animal experiments models. This will allow for a more precise simulation of biological processes within the human body," said Dr. Yuanrong Li, the first author on the paper.

The alveoli, primarily composed of alveolar epithelial cells, basement membrane, and capillaries, undergo various shape changes during respiration. "While there have been significant advancements in alveolar microphysiological systems, there remains a deficiency in suitable biomaterials for constructing alveolar basement membranes and controlling alveolar different deformation," said Li.

Inspired by the art of paper-cutting, the research team designed a biomimetic basement membrane coated with GelMA on a polycaprolactone (PCL) topological mesh surface. The PCL mesh is structured with circles and waves. When the biomimetic basement membrane is activated, the shape of the circles remains constant.

The larger the arc of the wave, the greater the deformation of the stretched wave, and consequently, the greater the deformation of the hydrogel near the wave. By altering waves of different curvatures, the deformation of the entire biomimetic basement membrane can be controlled.

Through material optimization, the research team selected a concentration of GelMA that matches the stiffness of the alveolar Extracellular Matrix (ECM). The Arg-Gly-Asp (RGD) ligand contained in GelMA aids in cell adhesion and fosters a more conducive alveolar microenvironment. Furthermore, the GelMA coating enables the cultivation of cells at the air-liquid interface, simulating the human air-blood barrier.

"This structural design is very exciting for us, because it can be used not only to simulate alveolar breathing, but also for other scenarios where local deformation needs to be controlled," Li says. The research team verified the effectiveness of this composite design through numerical simulations and cell experiments.

In the final stages of their study, the research team employed an alveolar microphysiological system to mimic the lung injury induced by mechanical ventilation. Subsequently, they administered Lopinavir/ritonavir as a means to alleviate the symptoms associated with ventilator-induced lung injury.

Alveolar microphysiological systems represent an innovative convergence of biology, medicine, and engineering, with the potential to transform a range of scientific disciplines including basic biology, physiology, pharmacology, toxicology, and drug discovery. Significant advancements have been achieved in the development of biomimetic basement membranes and bioreactors for these systems.

"Looking ahead, the focus should be on the creation of tools that are not only physiologically relevant but also user-friendly, reproducible, and cost-effective, in order to provide tangible benefits to the broader scientific community," said Professor He.

More information: Juqing Song et al, Advances in 3D printing scaffolds for peripheral nerve and spinal cord injury repair, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acde21

Provided by International Journal of Extreme Manufacturing