This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

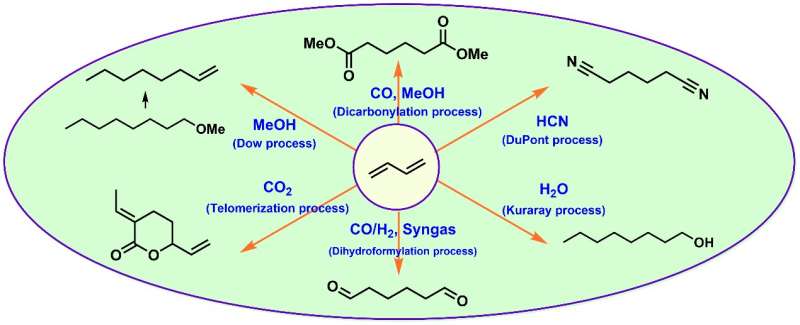

Industrially applied and relevant transformations of 1,3-butadiene using homogeneous catalysts

The use of 1,3-butadiene as a cheap and abundant raw material for new applications has attracted more interest in recent decades, specifically in the chemical industry. A recently published review covers several important homogeneously catalyzed processes and technologies that are currently used or have the potential to produce fine and bulk chemicals from 1,3-butadiene. This article focuses specifically on the application of homogeneous catalysts and presents representative examples for the readers.

For example, palladium-catalyzed telomerization of 1,3-butadiene offers versatile platform chemicals for the production of 1-octene, 1-octanol, and higher-value EVP lactones through the participation of diverse nucleophiles. Meanwhile, efficient di-functionalizations of 1,3-butadiene provide a straightforward access for the synthesis of various polymer precursors, including adiponitrile, adipaldehyde, and adipic diesters.

The development of efficient catalytic systems plays a key role in enabling atom-economic and selective processes. The review highlights that there are still many potential applications for 1,3-butadiene that are not currently being explored in the chemical industry. Overall, this review provides valuable information on industrially applied and relevant transformations of 1,3-butadiene using homogeneous catalysts that can be useful to researchers and professionals in the field.

Beller et al. published their review in Industrial Chemistry & Materials.

"The motivation behind this review was to provide a comprehensive overview of the current state-of-the-art in using 1,3-butadiene as a raw material for chemical production. This compound is abundant and relatively cheap, making it an attractive option for producing fine and bulk chemicals. However, there are still many challenges associated with using 1,3-butadiene as a feedstock, including its high reactivity and potential for unwanted side reactions," said corresponding author Professor Matthias Beller, Leibniz Institute for Catalysis e.V. (LIKAT).

"In this review, we cover several important homogeneously catalyzed processes that are currently used or have the potential to produce valuable chemicals from 1,3-butadiene. These include palladium-catalyzed telomerization, di-functionalization, and other reactions that can produce various chemicals and polymer precursors."

"We emphasize the importance of developing efficient catalytic systems that can enable atom-economic and selective processes. We provide examples of how different catalysts can be used to achieve specific chemical transformations with high yields and selectivity. The review also highlights some potential applications for 1,3-butadiene that are not currently being explored in the chemical industry."

"Efficient catalytic systems are critical for enabling selective and sustainable processes when using 1,3-butadiene as a feedstock. Advances in catalyst design have led to significant improvements in yield and selectivity for many chemical transformations involving this compound."

When discussing the future of utilizing 1,3-butadiene as a raw material for chemical production, Professor Matthias Beller stated, "I firmly believe that there is still a great deal of potential for exploring new applications of 1,3-butadiene within the chemical industry."

"It could, for instance, serve as a valuable feedstock for producing renewable chemicals or as a starting material for synthesizing novel materials with distinctive properties. Nevertheless, it will be crucial to continue advancing efficient catalytic systems and sustainable processes to surmount the obstacles linked with using this compound as a feedstock."

More information: Ji Yang et al, Industrially applied and relevant transformations of 1,3-butadiene using homogeneous catalysts, Industrial Chemistry & Materials (2023). DOI: 10.1039/D3IM00009E

Provided by Industrial Chemistry & Materials