This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Silver nanoparticles spark key advance in thermoelectricity for power generation

Several high-performance thermoelectric materials have been discovered over the past two decades, but without efficient devices to convert the energy they produce into emission-free power, their promise has been unfulfilled. Now an international team of scientists led by a University of Houston physicist and several of his former students has reported a new approach to constructing the thermoelectric modules, using silver nanoparticles to connect the modules' electrode and metallization layers.

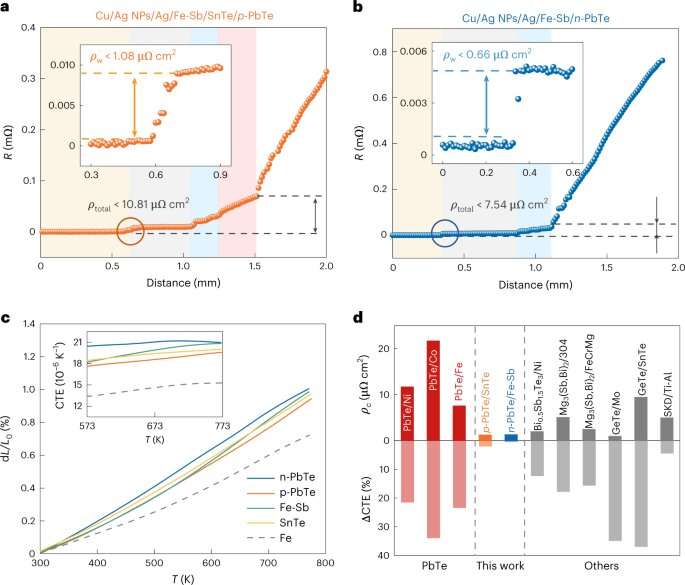

The work, described in a paper published May 1 in Nature Energy, should accelerate the development of advanced modules for power generation and other uses. The use of silver nanoparticles was tested for stability in modules built of three different state-of-the-art thermoelectric materials, designed to operate across a wide range of temperatures.

Thermoelectric materials have drawn increasing interest because of their potential as a source of clean energy, produced when the material converts heat—such as waste heat generated by power plants or other industrial processes—into electricity by exploiting the flow of heat current from a warmer area to a cooler area. But taking advantage of that ability requires finding a material that can connect the hot and cool sides of the material both electrically and thermally, without interfering with the material's performance.

The connective material, or solder, is melted to create an interface between the two sides. That means the solder must have a higher melting point than the operating temperature of the device in order to remain stable while the device is working, said Zhifeng Ren, director of the Texas Center for Superconductivity at UH and a corresponding author on the paper. If the thermoelectric material operates at hotter temperatures, the connective layer will re-melt.

But it can also be a problem if the connective material has too high a melting point, because high temperatures can affect the stability and performance of the thermoelectric materials during the connection process. The ideal connective material, then, would both have a relatively low melting point for assembling the module, so as not to destabilize the thermoelectric materials, but then be able to withstand high operating temperatures without re-melting.

Silver has valuable properties for such a connective material, with high thermal conductivity and high electrical conductivity. But it also has a relatively high melting point, at 962 degrees Centigrade, which can affect the stability of many thermoelectric materials. For this work, the researchers took advantage of the fact that silver nanoparticles have a much lower melting point than bulk silver. The nanoparticles returned to a bulk state after the module was assembled, regaining the higher melting point for operations.

"If you make silver into nanoparticles, the melting point could be as low as 400 degrees or 500 degrees C, depending on the particle size. That means you can use the device at 600 C or 700 C with no problem, as long as the operating temperature remains below the melting point of bulk silver, or 962 C," said Ren, who is also M.D. Anderson Professor of Physics at UH.

He worked on the project with five former students and post-doctoral researchers from the Ren research group; they are now at the Harbin Institute of Technology in Shenzhen, China, and the Beijing National Laboratory for Condensed Matter Physics at the Chinese Academy of Sciences in Beijing.

The researchers tested the silver nanoparticles with three well-known thermoelectric materials, each of which operates at a different temperature.

A lead tellurium-based module, which works at a low temperature of about 573 Kelvin up to about 823 K (300 C to 550 C) produced a heat-to-electricity conversion efficiency of about 11% and remained stable after 50 thermal cycles, according to the researchers.

They also used the silver nanoparticles as the connective material in modules using low-temperature bismuth telluride and a half-Heusler high-temperature material, indicating the concept would work for a variety of thermoelectric materials and purposes.

Different materials are used depending on the intended heat source, Ren said, to ensure the materials can withstand the applied heat. "But this paper proves that whatever the material, we can use the same silver nanoparticles for the solder as long as the applied heat does not go above 960 degrees C," in order to remain below the melting point of bulk silver, he said.

More information: Li Yin et al, Low-temperature sintering of Ag nanoparticles for high-performance thermoelectric module design, Nature Energy (2023). DOI: 10.1038/s41560-023-01245-4

Journal information: Nature Energy

Provided by University of Houston