This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

New hemp-based biomaterial to help with global microplastic pollution crisis

Plastic is cheap and light, and conceivably recyclable, which makes it an easy choice for packaging when it comes to food and cosmetics. But it's also potentially toxic and biologically harmful, making it a non-starter for many environmentally responsible and socially conscious companies in Canada and around the world.

Western chemistry professor Elizabeth Gillies, mechanical and materials engineering professor Aaron Price and their research teams worked with industry partner CTK Bio Canada to develop a new biodegradable, hemp-based material that could serve as a sustainable substitute for packaging needs for a wide variety of products.

"When it comes to packaging, plastic replaces things like metal and glass. Those are heavy and expensive," said Gillies, who is also the Canada Research Chair in polymeric biomaterials. "Glass recycling is not a very profitable business and while many plastics are potentially recyclable, it often doesn't happen in practice."

This lack of recycling, compounded by a global microplastics pollution crisis, led Gillies and her team to find a degradable 'plastic' to solve the problem, or in this case, a hemp-based product.

Hemp is a sustainable agricultural crop that requires minimal resources to grow. It's also a waste product of Canada's ever-growing cannabis industry, making it a free resource that would otherwise be destined for a compost heap or the landfill. These reasons alone make hemp a suitable candidate, but its structural makeup makes it a clear winner.

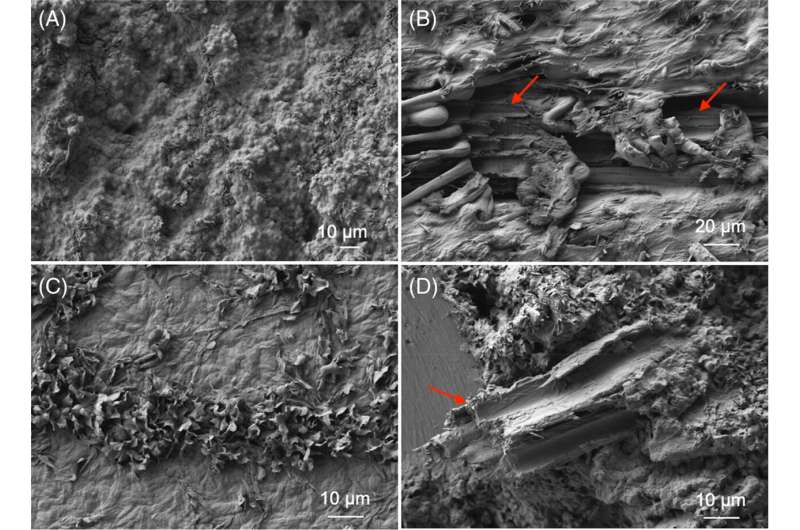

"Depending on the form, hemp can have a fibrous structure, which acts perfectly as a reinforcement for materials," said Gillies. "Basically, hemp is stronger and more malleable than many other biomaterials."

The goal of the project with CTK Bio was to find a proxy for widely used industrial plastics such as high-density polyethylene pellets, which could be fed directly into the same manufacturing process currently used to produce plastic packaging. Gillies and her collaborators used ground hemp stalk powder to serve as filler during production of packaging.

While mechanical properties like strength and malleability are not quite the same as the current packaging plastics, the new biomaterial approaches the necessary qualities, depending on the application, and they do exhibit degradability, which is key.

In terms of cost, biomaterials are currently more expensive to produce than plastic, but companies are working to optimize and reduce pricing, so it is expected costs will fall in the coming years as these technologies improve.

Results of the study validate the new hemp-based biomaterial's potential as a plastic alternative and open the door for future industry collaborations and partnerships. This new biomaterial is outlined in a new study in the Journal of Polymer Science.

More information: Zhengyu Deng et al, Biobased composites of poly(butylene furanoate) copolymers and hemp, Journal of Polymer Science (2023). DOI: 10.1002/pol.20230060

Provided by University of Western Ontario