This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Standard reference cantilevers for atomic force microscopy spring constant calibration

Atomic force microscopy (AFM) is a popular technique for interrogating surfaces on the micro and nano scales. The most common use for AFM is imaging; however, there are a variety of more specialized AFM techniques that can be used to determine electrical, mechanical, and chemical properties of surfaces. To adequately control the application of forces to surfaces for these techniques (especially mechanical property measurements), accurate stiffness calibrations of test cantilevers should be used.

There are a variety of test cantilever stiffness calibration techniques available, based on dimensional, static force and displacement, and dynamic vibrational methods, but in general, these have large uncertainties in the range of ± 10% to ± 30% and unknown accuracy. More rigorous calibrated balance techniques, with SI traceability have been pioneered, mostly by National Metrology Institutes (NMIs), but their complexity, expense, and time-consuming operation make them an out-of-reach technique for most AFM researchers. The reference cantilevers represented by NIST SRM 3461 are an accurate and precise force calibration artifact for use in the field.

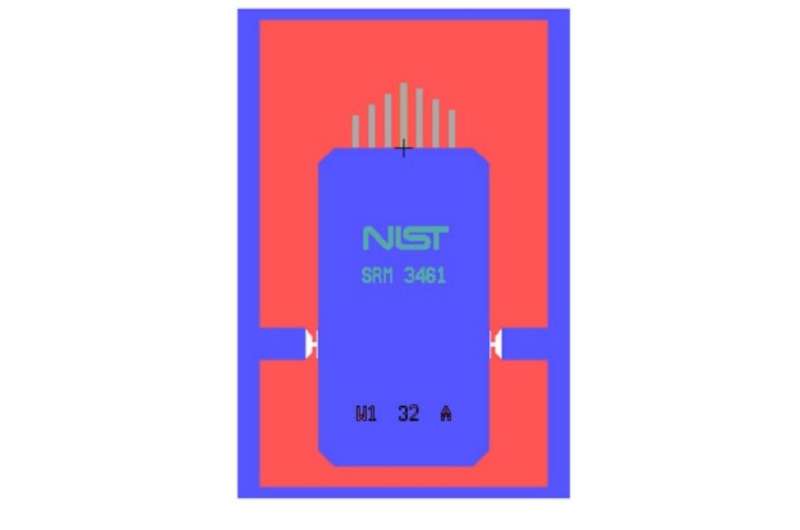

SRM 3461 is a silicon microfabricated device containing seven cantilevers of carrying length and stiffness is used for validating methods for determining the stiffness of atomic force microscope (AFM) cantilevers as well as directly calibrating AFM test cantilevers using the reference cantilever method.

A unit of SRM 3461 consists of one silicon microfabricated device approximately 1.6 mm by 3.0 mm containing an array of seven (7) uniform, rectangular cantilevers of varying length and stiffness at the end. Each cantilever is nominally 50 μm wide and 1.45 μm thick with lengths of 300 μm to 600 μm in steps of 50 μm. The device comes adhered to a polydimethylsiloxane (PDMS) gel film in a protective antistatic enclosure with a removable top. It can be used as-is by temporarily removing the top or could be carefully transferred to an appropriate alternative holder. SRM 3461 was microfabricated, packaged, and calibrated in a clean room environment to minimize exposure to dust, debris, and contaminants. The packaging provided is intended to protect the device during shipping and storage in non-cleanroom laboratory environments. The device should be stored at room temperature (20 °C ± 5 °C) when not in use.

More information: Richard S Gates, Certification of Standard Reference Material® 3461 Reference Cantilevers for AFM Spring Constant Calibration, NIST Special Publication (2022). DOI: 10.6028/NIST.SP.260-227

Provided by National Institute of Standards and Technology

This story is republished courtesy of NIST. Read the original story here.