A pressure-sensitive device capable of characterizing gases using structural colors

NIMS, Harvard University and the University of Connecticut have designed and fabricated a simple device capable of imaging a gas injected into it in multiple colors in accordance with its gaseous properties, enabling chromatic discrimination of different gases. This user-friendly device converts the pressure generated by an injected gas into structural colors, thereby imaging it. This technology may potentially have a wide range of applications, such as environmental monitoring, safety assurance and health care.

Imaging of gases is important in many gas-related basic and applied research projects as almost all ambient gases are colorless and invisible. Only a few methods for imaging ambient gas flow have been developed (e.g., the use of infrared cameras capable of detecting temperature changes and airflow measurements by means of releasing tracer particles into the air).

These methods require elaborate equipment and are unsuitable for imaging different types of gases in a consistent manner. In addition, the images they produce are unfit for the analysis of gaseous characteristics. A simple method capable of imaging and analyzing all types of gases may have a wide variety of applications, such as image-based measurements.

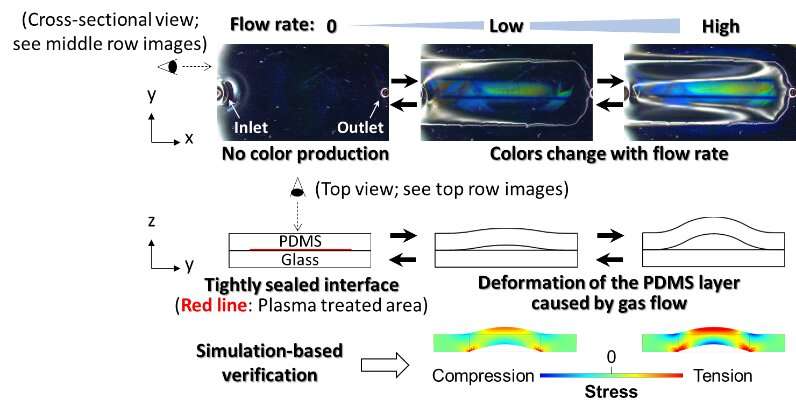

This research team recently fabricated a device capable of imaging and differentiating various gases using a wide range of colors (i.e., structural colors) through a simple procedure: polydimethylsiloxane (PDMS)—a soft material—was first shaped into a slab. Part of the PDMS surface was then treated with argon plasma. The plasma-treated PDMS slab was placed on the surface of a glass substrate with its plasma-treated surface down, and they came into complete contact.

The plasma-treated PDMS surface forms a periodic ripple-like micropattern when compressed by an injected gas passing through the tight boundary between the PDMS and glass layers. This compression and resultant micropattern formation lead to the production of structural colors. This mechanism is applicable to the imaging and differentiation of any type of gas. When the incoming gas flow is discontinued, structural colors disappear completely.

The degree of PDMS deformation depends on the flow rates, viscosities and densities of injected gases. As all gases have unique viscosities and densities, this device can be used to differentiate and analyze gas samples based on these properties under a constant flow rate.

In future research, the team will work to optimize the device by improving its sensitivity with the goal of making it compatible with various applications (e.g., identification of ambient gases and biological samples). The team will also consider developing a new gas identification technique by combining it with image recognition and machine learning techniques and fabricating a small, CCD (charge coupled device)-integrated device with a simple structure.

The study is published in the journal Advanced Science.

More information: Kota Shiba et al, Visualization of Flow‐Induced Strain Using Structural Color in Channel‐Free Polydimethylsiloxane Devices, Advanced Science (2022). DOI: 10.1002/advs.202204310

Journal information: Advanced Science

Provided by National Institute for Materials Science